Uncompromised Quality | Ski Factory

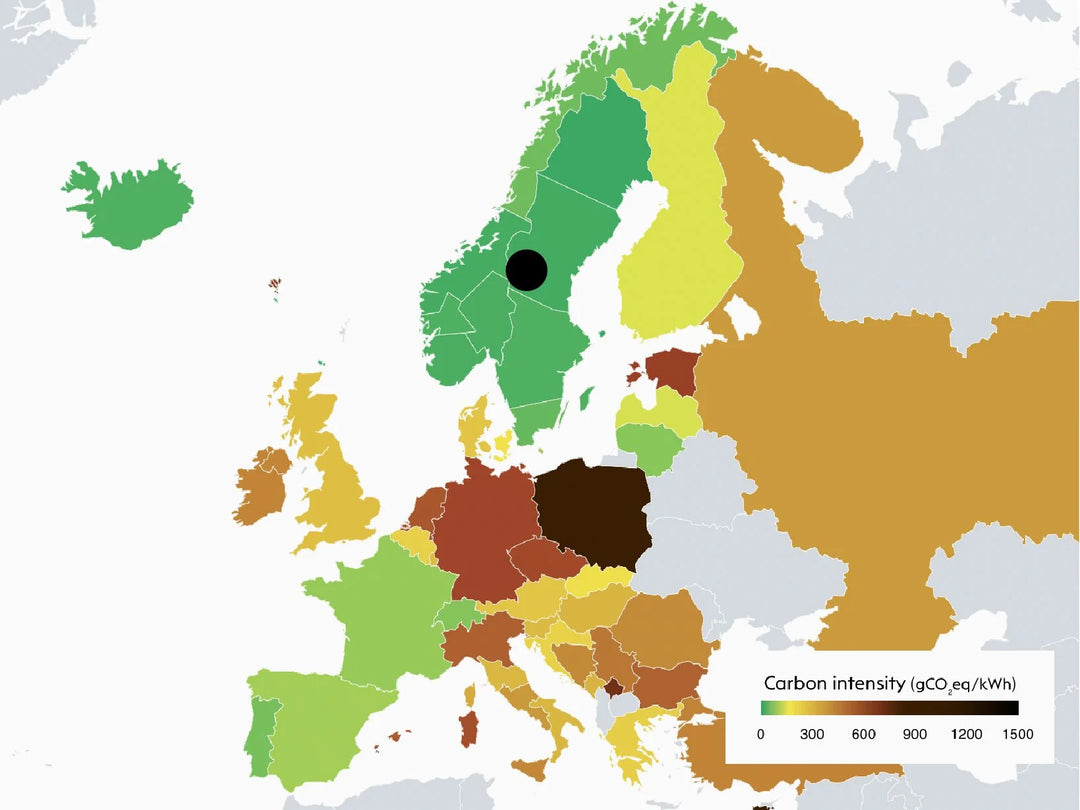

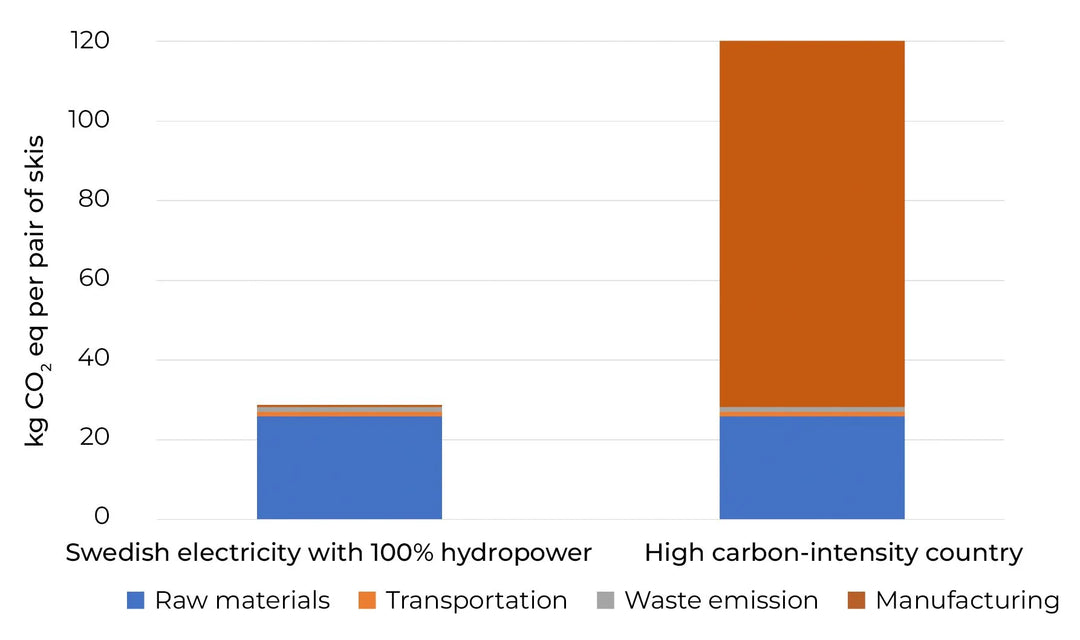

Over our 15 years of manufacturing skis, we have moved from handcrafting ourselves, to multiple different factories, in search of the best ski around. Our aim has always to produce the best skis on the market, to last a lifetime. We believe we now match that aim, producing the best, long lasting, skis in the industry. We believe in this so much, we offer a lifetime warranty on all our skis. The bonus? It is done with 100% renewable energy.

The origin of Åre Skidfabrik began in 1981 when Stefan Cederberg and Patrik Söderlund began building snowboards in their parent’s garage in Frösön. It is an origin story we connect with.

After 10 years of manufacturing for local snowboarders under company name ‘Extrem’, Patrik and Stefan moved further inland to Scandinavia’s largest ski resort, Åre. Upgrading their production facility from garage to an 800 square meter factory. By 1998, Extrem began manufacturing skis under the same name.

In 2011, Extrem was restructured to Āre Skifabrik which further evolved in 2015 when they began manufacturing for other ski brands. The rapid expansion of the successful factory reached another level in 2020 when investment was placed into efficient machinery, focused sustainability and a praised work environment. We are proud to work alongside the highly skilled Åre SkidFabrik team and their 40+ years of experience, producing skis out of the most environmentally friendly ski factory in the industry.